water ring vacuum pump causes of scaling and preventive measures

Water ring vacuum pump and compressor are used to pump or press gas and other non corrosive, water-insoluble and solid particles free gas, so as to form vacuum or pressure in a closed container, so as to meet the requirements of specific process flow. A small amount of liquid is allowed in the gas inhaled or compressed. In the working process, water ring vacuum pumpcompresses the gas in the isothermal state, so it is not easy to cause danger when it compresses or sucks flammable and explosive gas, so it is more widely used. Therefore, it is of great application value to analyze the scaling reasons and preventive measures of water ring vacuum pump.

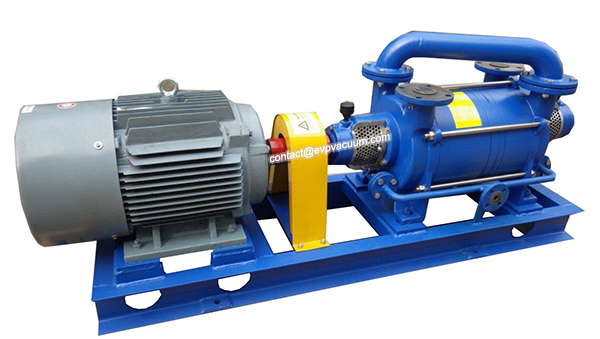

water ring vacuum pump introduction:

The water ring vacuum pump and compressor system is composed of vacuum pump (compressor), coupling, motor, steam water separator and pipeline. The working process of vacuum pump, compressor and steam water separator is as follows: the gas enters the vacuum pump or compressor through the pipeline through the valve, then it is discharged into the steam water separator through the air guide elbow, and then it is discharged through the steam water separator exhaust pipe. When used as a compressor, the steam water mixture discharged from the compressor is separated in the steam water separator, and the gas is delivered to the system of the gas to be compressed through the valve, while the water is left in the steam water separator, and the water level in the steam water separator is adjusted by the automatic overflow switch. When the water level is higher than the required water level, the overflow switch is opened, and the water overflows from the overflow pipe; when the water level is low When the required water level is reached, the overflow switch is closed, and the water level in the steam water separator rises to reach the required water level. The working liquid in the vacuum pump or compressor is supplied by the steam water separator (or tap water). The size of the water supply is adjusted by the valve on the water supply pipe. The difference between gas suction and pressure delivery system is only that the internal structure of steam water separator is different. When pumping gas, the pressure at the suction port is lower than atmospheric pressure, while the pressure at the exhaust port is equal to atmospheric pressure, and there is only overflow pipe in the steam water separator; when pressing gas, the suction port is under atmospheric pressure (or vacuum state), and the pressure at the exhaust port is higher than one atmospheric pressure. In order to ensure the gas pressure, the water level of the steam water separator is controlled by the overflow switch.

water ring vacuum pump scaling causes:

With the beginning of scaling in water ring vacuum pump, the heat transfer environment in the pump is gradually destroyed, the heat exchange frequency will be lower and lower, and the scaling speed will be faster and faster. The causes of scale are as follows:

(1) Thermal decomposition: after the circulating water with hardness component enters the vacuum pump, the water ring is formed in the pump body with the rotation of the water ring vacuum pump, which makes the bicarbonate dissolved in the water decompose gradually, and the precipitation which is difficult to dissolve in the water is precipitated to form scale.

(2) Solubility decrease: salts such as ca-so4, CaSiO3 and CaCO3 with negative solubility temperature coefficient decrease solubility with the increase of circulating water temperature, thus precipitate and form scaling.

(3) Mutual reaction: in the operation process of vacuum pump, salts with high solubility in circulating water react with other salts to form insoluble substances and scale.

(4) Evaporation and concentration. Due to the continuous work and heating of circulating water, evaporation and concentration are inevitable, which makes the concentration of dissolved salt in water increase continuously, and precipitates and forms scale when it reaches saturation.

water ring vacuum pump scale analysis:

In the operation of water ring vacuum pump, the scale produced includes salt scale and scale, and its composition varies with different water sources. The biggest harm of fouling is to reduce the water flow and increase the flow resistance, affect the normal water supply, reduce the heat exchange efficiency, improve the water temperature, and accelerate the formation of salt scale. Sometimes it may even cause corrosion under the scale. When the scale is deposited seriously, it may cause abnormal sound of the vacuum pump, decrease of efficiency or accidental shutdown of the stuck impeller. The source of the dirt varies from time to time and from place to place. In actual operation, it is necessary to carefully analyze whether there is inflow of waste water, whether there is sediment, dust, slime or other causes of water pollution.

water ring vacuum pump scale prevention measures:

The above analysis shows that the main cause of vacuum pump scaling is that the water quality and operating temperature of circulating water exceed a certain index. The water quality index, especially the hardness of water, has the greatest influence. Therefore, it is necessary to reduce the hardness of water as much as possible and control the working temperature of circulating water in order to solve the scaling problem of vacuum pump. Therefore, in the process of circulating cooling water operation, the return water temperature and return water volume of each pump are tested to ensure that the normal water supply and return water temperature of each water ring vacuum pump do not exceed 40 ℃. The water supply can be controlled by valves. If the return water temperature exceeds the specified value, it is necessary to supplement low temperature cold water or use other cooling methods to reduce the temperature of the softened water in the softened water pool. Secondly, the pump body drain valve of the water ring vacuum pump can not only discharge the accumulated water in the pump normally, but also wash the dirt and water in the pump regularly by using the water pressure of the pump body in the process of re operation. On the one hand, it can prevent the dirt from accumulating, on the other hand, it can prevent the water slag from turning into scale.

The scaling problem of water ring vacuum pump has a more complex formation mechanism. Correct analysis of water quality index and operation parameters is the key to find out the correct preventive measures. In addition to the water temperature control box to wash the pump regularly, water treatment is the most important link to prevent scaling of the water ring vacuum pump body.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.