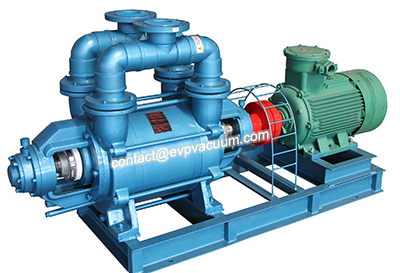

Vacuum pump in yarn steamer application

The main purpose of the steaming machine is to combine and twist the continuous yarns with weaving conditions, and then set them, that is, to stabilize the twist under a certain pressure and temperature, and to obtain a balanced and non twisted yarn. The use process of the yarn steamer is vacuum preheating humidification heat preservation constant temperature vacuum cooling. The vacuum pump for vacuumizing is generally water ring vacuum pump, the working pressure of the yarn steamer is – 0.085-0.1mpa, and the water ring vacuum pump can extract a certain amount of condensable gas. The yarn steaming machine with vacuum pump can steam yarn or fabric evenly, accurately and softly from low temperature to high temperature. The micro-computer is used to control the steam steaming process, and the temperature is controlled to ± 0.5 ℃, so as to ensure the accurate reproduction of the steam steaming process according to the budget process, avoid the generation of condensation water to the greatest extent, and make the yarn get uniform and soft steam steaming treatment. Therefore, it can be used in this process. How large a water ring vacuum pump is to be used depends on the size of the yarn steamer and its own time requirements.

Vacuum pump principle of selecting

Here is a brief introduction to the principle of selecting vacuum pump:

Since its establishment, Vacuum Equipment Co., Ltd. has been committed to research, development and production of liquid ring vacuum pump, rotary vane vacuum pump, slide valve vacuum pump and other mechanical products. The company has Foundry Branch, vacuum pump branch, with all aspects of outstanding professionals, so that the products are more perfect. Since the product was launched, it has won the trust of users with its excellent quality and reasonable price.

1. Structure of vacuum pump: for pumping corrosive gas, it must be made of corrosion-resistant material or lining corrosion-resistant material. The vacuum pump with lubricating oil can not be selected for pumping the gas working with oil.

2. Meet the process requirements: if the amount of non condensable gas on the top of the decompression tower is large, the steam jet vacuum pump must be selected, because it has the characteristics of high vacuum degree, simple structure, convenient operation, etc., which creates a very high vacuum in the decompression tower, is conducive to fractionation under decompression, and ensures the product quality.

3. Sufficient gas extraction rate: within the allowed time, the gas to be extracted can be extracted to ensure the normal production.

4. Working time: continuous working time can guarantee the basic requirements of a process cycle, and cannot affect production due to short continuous working time.

Whether it is the first user or the subsequent customer support, to provide customers with the best quality and service, is always the company’s commitment to you. Careful and fast after-sales service, always for the user’s sake. “Unity, pragmatism, innovation and development” is the company’s guiding principle. We will keep in touch with our peers and constantly develop the vast market at home and abroad. Gradually establish a perfect marketing network and create brilliance with customers and users.

Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.