DLV Series Double Stages Liquid Ring Vacuum Pumps

Introduction:

DLV series two stage liquid ring vacuum pump is our new design based on 2SK pumps and combines Germany double-stage pump design criteria. This series has two compression processes, with steady suction speed in high vacuum, or keeping the high vacuum in a wide range of suction speed. Its efficiency in high vacuum is 35%-40% higher than that of single stage pump, but with less energy consumption.

Advantages:

1. Wider range of suction pressure. Compared to other double stage pumps (suction pressure 50mbar-150mbarA), DLV pump works in 25mbar~1013mbar pressure, with less energy consumption, with15%-20% lower than traditional ones.

2. All kinds of models to fulfill various process requirements.

3. Materials are optional to make the pump possible to work in various harsh environment, Such as carbon steel, stainless steel, dual-phase steel, titanium, etc .

4. Single or double mechanical seal and several flush method.

5. Precise casting, high standard accessories, imported bearing; high efficiency and energy saving.

Application:

DLV series pumps are very suitable for the process of vacuum drying, evaporation, distillation, concentration, filtering, degassing in industry of food, pharmacy, chemical, power plant, paper making, textile, metallurgy etc.

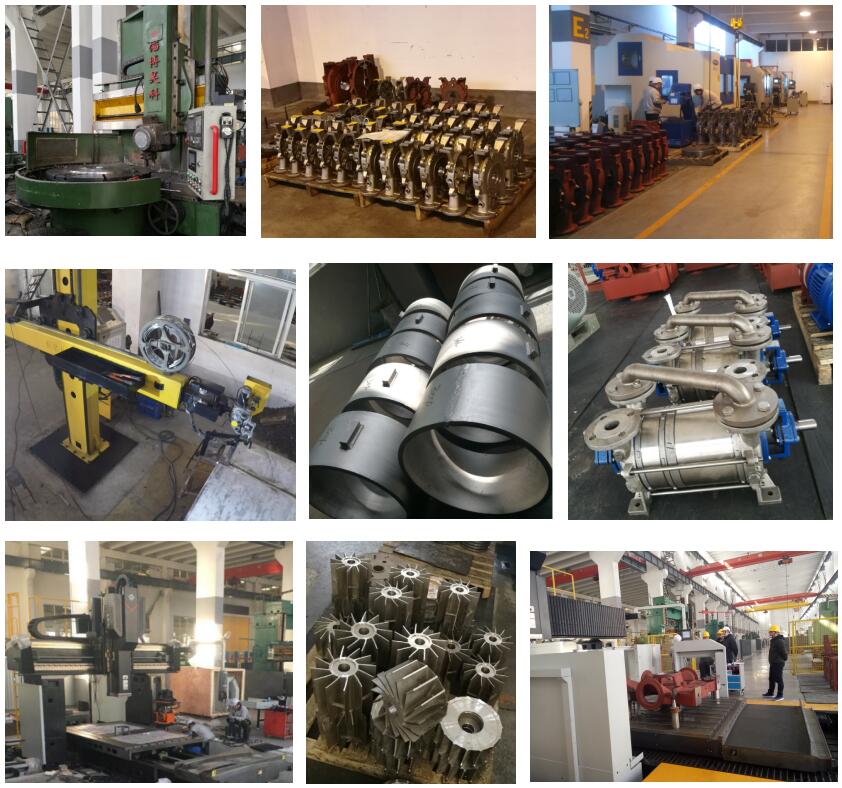

Product Specific Procedure Description (Picture Display)

Packing &shipping

Delivery:

1.Pumps in stock will be delivered in 3 working days after standard tests.

2.For 5~10 units: about 35 working days; 11~20 units: about 45 working days.

3.If urgent, please tell, we will try to meet.

Package:

1.Standard wooden case or carton, to meet all countries’ importing rules.

2.Pumps are fixed inside to avoid delivery damages.

3.Manual & quick-wear parts are included.

| Model | Motor

speed |

Motor power | Max. suction capacity | Min. inlet pressure | Inlet&outlet port | |||

| kw | HP | m3/h | CFM | mbar | Inch Hg | mm | ||

| DLV-110/

DLV-120 |

1450 | 3.0 | 4 | 110 | 65 | 33 | 1.0 | DN 40 |

| 1750 | 4.0 | 5.5 | 132 | 80 | 33 | 1.0 | ||

| DLV-140 | 1450 | 4.0 | 5.4 | 145 | 85 | 33 | 1.0 | DN40 |

| 1750 | 5.5 | 7.4 | 174 | 102 | 33 | 1.0 | ||

| DLV-180 | 1450 | 5.5 | 7.4 | 186 | 109 | 33 | 1.0 | DN40 |

| 1750 | 7.5 | 10.1 | 223 | 131 | 33 | 1.0 | ||

| DLV-300 | 1450 | 7.5 | 10.1 | 283 | 167 | 33 | 1.0 | DN50 |

| 1750 | 11.0 | 14.8 | 314 | 185 | 33 | 1.0 | ||

| DLV-350 | 1450 | 11.0 | 14.8 | 342 | 201 | 33 | 1.0 | DN50 |

| 1750 | 15.0 | 20.1 | 411 | 242 | 33 | 1.0 | ||

| DLV-400 | 1450 | 15.0 | 20.1 | 425 | 250 | 33 | 1.0 | DN50 |

| 1750 | 18.5 | 24.8 | 475 | 280 | 33 | 1.0 | ||

| DLV-500 | 1450 | 18.5 | 24.8 | 501 | 294 | 33 | 1.0 | DN65 |

| 1750 | 22 | 29.7 | 590 | 347 | 33 | 1.0 | ||

| DLV600 | 1450 | 22 | 29.7 | 616 | 362 | 33 | 1.0 | DN65 |

| 1750 | 30 | 40.5 | 739 | 434 | 33 | 1.0 | ||

| DLV800 | 975 | 30 | 40.5 | 862 | 507 | 33 | 1.0 | DN100 |

| 1175 | 37 | 50 | 1032 | 607 | 33 | 1.0 | ||

| DLV1200 | 975 | 37 | 50 | 1252 | 736 | 33 | 1.0 | DN100 |

| 1175 | 45 | 60 | 1407 | 1407 | 33 | 1.0 | ||

| DLV1600 | 975 | 45 | 60 | 1589 | 935 | 33 | 1.0 | DN100 |

| 1175 | 75 | 101 | 1717 | 1010 | 33 | 1.0 | ||

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.