Damage Analysis Factors of Dry Screw Vacuum Pumps

I.Analysis on Corrosive rotor surface

Vacuum pump feed medium containing sulfur dioxide, water, sulfur dioxide combined with water to generate sulfurous acid, sulfurous acid on the metal corrosive effect, in order to prevent rotor, pump chamber corrosion, the surface of the rotor and pump Teflon coated layer. Corrosion of the rotor and pump chamber shows destruction of the layer, sulfite has corroded the pump chamber.

II.Analysis on Teflon coating damage in the rotor and the pump chamber

It may have two major reasons to result such damage:

① Solid particles enter the pump chamber and solid particles cause damage to the coating;

② Chemical substances in the pump chamber and the rotor to form a plastic, carbonized carbide hard, destroy the rotor and pump coating;

③ Others

1、Solid particle damage analysis

Check the pump inlet equipment and the piping to see whether have solid particles exist, such as metal fragments, iron cutting and so on.

2、Gum coking damage analysis

Below picture Fig 1 is the pump inlet port attachments photo, the material is dark brown, the analysis contains iron, carbon, oxygen, etc., is a butadiene, sulfolane and other polymeric material, the material bonded to the pipe wall . If the material is bonded to the pump chamber and the rotor surface, it hardens easily and the layer of rotor surface is destroyed.

Fig. 1 attachments on the pump inlet port

3、Processing factor analysis

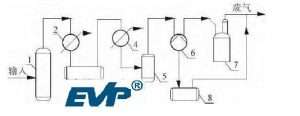

Below picture Fig 2 the outlet pressure of vacuum pump is 80kpa (A), which is negative pressure, and the pump liquid phase pressure is normal, under normal circumstances, resulting in the pump outlet liquid can not normally enter the underground liquid tank, and the formation of reflux, resulting in the pump outlet liquid material accumulation , The liquid material containing sulfurous acid, pump outlet concentration of sulfuric acid solution to the formation of the impact of corrosion of the pump, it should be said that the pump outlet liquid reflux is the main reason for the pump rotor and pump chamber corrosion.

Fig. 2 Reduced pressure distillation process flow diagram

tags: dry screw vacuum pump

Edited by Catherine Qin / EVP Vacuum Solution

Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.