Notes and Possible Problems of Roots Vacuum Pump

1.Simple introduction of Roots Vacuum Pump

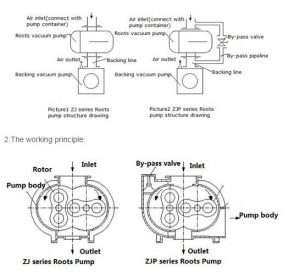

Roots vacuum pump, also known as mechanical booster pump, uses two eight-shaped rotor in the pump casing for synchronous rotation, so as to complete the process of inhalation and exhaust. Since main parts such as the pump casing, rotor and the end cap in the pump in operation work without relative movement between the contacts, the pump has stable performance in running with long service life, low maintenance costs. At present, this pump is widely used in vacuum smelting, vacuum welding, vacuum casting, vacuum spraying, vacuum drying, vacuum power experiments and chemical vacuum manufacturing, vacuum devices in the vacuum range .

Regarding the aspect of structure, Roots vacuum pumps in EVP are mainly divided into two types: ZJ series without by-pass valve, ZJP series with by-pass valve. About differences between ZJ and ZJP, please kindly see:

https://www.evpvacuum.com/newsview-255-358-Relationship_and_difference_between_ZJ_ZJP.html

Main points in operation:

Operation must be strictly in accordance with the specifications of Roots vacuum pump user manual. In normal conditions, the inlet pressure of roots vacuum pump is below 133 X 102Pa, the maximum inlet pressure should not exceed its maximum allowable inlet pressure. If more than, although ZJP Roots vacuum pump has bypass valve with automatic protection, it is only the motor overload protection and the pump can also overheat if it is operated for a long time.

3. Possible problems and solutions:

4.Real case:

One customer contacted us, the roots pump that they used in Vacuum Coating System (Not produced in EVP) has heavy oil foaming, please see below pictures:

According to the description and pictures, we listed below possible reasons:

1. Foam may be caused by moisture entering the pump.

2. Foam may be due to prolonged use of oil without replacement.

3. Foam may be cased by oil-sealing abrasion.

4. Foam may be caused by gas leaked into the pipe.

Solutions:

1. Because the backing pump is an oil-sealed rotary vane pump with a gas-operated valve and the intake air is confirmed not to contain a large amount of water vapor, this reason may not be possible.

(Note: If the intake air contains a lot of water vapor, please install a condenser in front of the pump.)

2. Drain all oil in the Roots pump, then add a small amount of new oil, and then released, and finally let shaft seal cavity and oil cup filled with oil, gearbox and bearing box of lubricating oil Add to the oil window diameter of 2/3 ~ 3/4 height.

(Note: under normal circumstances, please change oil after 50-hour running of the Roots pump, then change the oil according to the actual situation of work.)

3. Check if the oil-seal is worn.

4. Check all connecting lines and valves to ensure that no gas is admitted to the system.

After the above methods of testing, the customer found that foaming in the oil reduced largely also vacuum pressure and suction capacity improved. We helped him solved this problem.

Tags: Roots pump, Roots vacuum pump, Booster pump, Mechanical booster pump, Pump oil, Lubricating oil.

Edited by: Edited by Emily Fu/ EVP vacuum solution

Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.