Feature of oil lubrication ,grease lubrication and magnetic levitation molecular pump

Molecular pump is a vacuum pump that transfer momentum to the gas molecules by high-speed rotation of the rotor to get directional speed, gas molecules will be compressed and was driven to the exhaust port.

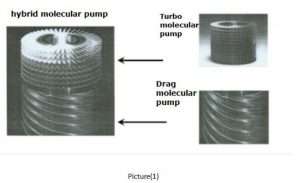

The molecular pumps are distinguished according to rotor structural characteristics as below:

1. Turbo molecular pump (The high-speed rotation of the rotor blades and stationary vanes to achieve the extraction of gas. This pump usually works in the molecular flow state.)

2. Drag molecular pump (the gas molecules collide with a high-speed rotor to get momentum and are driven to the pump’s outlet.)

3. hybrid molecular pump (a compound type combined by turbo molecular pump and drag molecular pump.)

Rotor is shown as below picture(1)

We will discuss turbo molecular pump’s classification and features as below:

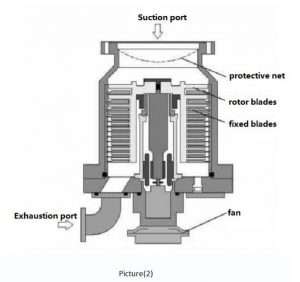

Turbo molecular pump is a vacuum pump making molecule compressing directly and flowing by using mechanical kinetic energy gas when in a molecular flow state. Molecular pump is a good choice for obtaining a clean vacuum environment. Because turbomolecular pump is better than cryogenic pump, ion pump and diffusion pump in some certain case . Therefore, turbomolecupar pump are chose under normal circumstances.

Turbomolecular pump structure is as follows picture(2):

Distinguish from bearing characteristics, EVP molecular pump can be divided into following three categories:

1. Oil lubrication molecular pump

2. Grease lubrication molecular pump

3. Magnetic levitation molecular pump

Oil lubrication molecular pump features: bearing with oil lubrication.

Most turbomolecular pump rotors are used oil lubrication bearings. Because this bearing is on the exhaust side of the rotor, the oil vapor will not reach the inlet of the turbomolecular pump.

At the end of high pressure, oil flow through the bearing can be used to dissipate the gas frictional heat. At low pressure, the friction of the oil itself causes the rotor temperature to increase.

Grease lubrication molecular pump’s features: bearing with grease lubrication.

Generally low effective viscosity and very low vapor pressure of the bearing with grease to prevent the turbo molecular pump from misoperation, especially when the rotor is running at high speed to prevent high velocity oil from entering the inlet .

oil and grease lubricated molecular pumps are also called mechanical bearing molecular pumps. And the performance of its oil or grease must meet the following three conditions:

A. with good lubrication performance when high speed;

B. The saturated vapor pressure is lower than backing pump’s.

C. Appropriate viscosity as well as bearing cooling fuction.

Mechanical bearings molecular pump features are as follows:

(1) clean, no oil vapor reflux. Mechanical bearings molecular pump can work accoring operating rules without any trap. It can provide a very clean vacuum environment for the drawn vessel and does not contain any hydrocarbons.

(2) easy to use. In many applications, mechanical bearing molecular pumps do not need high vacuum valves or rough vacuum valves. Press the button and the pump start working. And mechanical bearings molecular pump installation direction is not limited, it can be installed in any direction.

(3) Strong Gas delivery capability. Most mechanical bearing molecular pumps are strong capable of delivering light gases such as hydrogen and helium. So it is very suitable for ultra high vacuum process operation.

(4) Suitable for ultra-high vacuum applications. A good sealed and degassing mechanical bearings molecular pump, coupled with a good performance of double-stage rotary vane pump (or the same performance of dry pump), the ultimate vacuum can generally reach 10-9 ~ 10-10Torr (i133.3 ~ 13.33 nPa). If a molecular pump connect with another a molecular pump with good sealed and well-degassing metal pump, the general limit pressure is in 1 × 10-10 ~ 1 × 10-11Torr ( 13.33 ~ 1.333nPa) .

(5) Good performance under high pressure. Some molecular pump inlet pressure works in 10-1 ~ 10-3Torr (13.33Pa ~ 133.3mPa).

(6) cycle time is short. Most molecular pumps, especially smaller, require about 1 ~ 3min to reach the normal operating speed.

(7) Using time is long when working normally. in some applications, the normal use of the molecular pump is superior to other pumps.

Magnetic levitation molecular pump using magnetic force to make the rotor suspended in the air so that the rotor and stator do not contact when working.

Its characteristics are as follows:

(1) without any oil, can be completely non-oil.

(2) the life of the bearing is very long due to no mechanical contact between the rotor and the stator,

(3) Compared with the traditional bearings, the rotor can work with high speed.

(4) low vibration and noise.

(5) Pump installation is not limited, it can be installed at any angle.

(8) Rotor with high-strength aluminum alloy and a high-speed milling forming

(9) self-balancing technology vibration is minimal

Compared to ordinary molecular pump, its bearings do not need lubrication, there is no problem about oil pollution.

Magnetic levitation molecular pump bearings are the most crucial parts, reference picture (3)is as below:

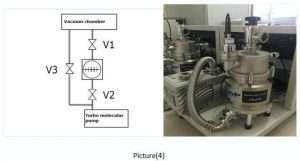

EVP not only provide a single molecular pump but also molecular pump system, reference pictures is as follows:

Tags:molecular pump, hybrid molecular pump,Grease lubrication molecular pump

Edited by Nancy Zhang / EVP vacuum solution

Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.