The function and principle of gas ballast valve

Due to contain a certain amount of water vapor in the atmosphere, so when the vacuum pump working the suction air also contain some non-condensable gas and the mixture of permanent gas.This gas mixture is compressed within the pump exhaust process, if partial pressure of non-condensable gas pass than the pump under the temperature of saturated vapor pressure, then they will condense and mixed with pump oil, with oil circulation.When they returned to the high vacuum evaporation and steam again.Increasing with the pump running, the condensation, the limit of the vacuum pump and pumping speed reduced.Humidity is bigger when pumping the gas, the pump oil pollution is more serious, sealing of pump, lubrication and cooling performance is poor, often that change new oil.

Gas ballast valve is to prevent the steam condensation in order to avoid the effective method to oil pollution.This method is to room temperature dry air hole bullishness of town into the compression chamber of pump and is pumped gas mixture.When the mixed gas compression to the exhaust pressure, due to the aeration effect makes the steam partial pressure can maintain the pump temperature under the condition of saturated vapor pressure, and steam will not together with the other gas condensation is to the pump.Gas is pumped, the more content of steam in mixed with dry gas amount is required.

Adopts the method of gas ballast, although achieved the purpose of exclusion of steam, but due to the aeration increasing the potential breakthrough to leak into the atmosphere to the suction side, so to have influence on the pumping speed and limiting vacuum pump.Pump in the aeration process, and its ultimate vacuum than not aeration falls 1 ~ 2 orders of magnitude.Generally when use, first to use the gas ballast valve aeration can non-condensable gas.Wait until after the steam ejector basic, can close the gas ballast valve and continue to smoke gas, after a certain period of time, can be reached when not in aeration limit vacuum pump.

Due to the method of gas ballast is mainly to prevent the pump in the process of compressed vapor condensation, so for those who are from the gas phase state can dissolve in the pump oil vapor ejector effect is poor.

Device with a gas ballast mechanical vacuum pump which include oil sealed rotary vane vacuum pump, and the purification of oil pump function: after the oil pump is a small amount of condensation water pollution, as long as the pump inlet to block, and then open the gas ballast valve, suction operation after a certain time, oil pump can restore the original performance.

Rotary vane vacuum pump air ballast valve

The gas ballast valve rotary vane vacuum pump for pumping condensable gas, usually set up by the gas pump suction as well as for permanent gases and can be a mixture of non-condensable gas. In the process of compression and exhaust. When the non-condensable gas partial pressure than corresponding saturated vapour pressure of the gas pump temperature, experience of condensation and condensable chi mixed in the oil pump. Along with the oil circulation pump, and return to the high vacuum side to evaporate into steam. This will affect the pump pumping performance. Increase the pump oil pollution. Gas ballast valve or aeration method can effectively prevent the non-condensable gas condensation, namely in the compression process through the control of a permanent gases (usually a room temperature drying air) by the air holes with compressed gas, causing the non-condensable gas partial pressure have not reached before the corresponding saturated vapor pressure pump temperature, the pressure of compressed gas has reached exhaust pressure, exhaust valve opens. Condensable gas together with permanent gases expelled. Mechanical vacuum pump oil seal type is generally equipped with a gas ballast device, so also called gas ballast pump. Air ballast valve (air mixing valve) is composed of throttle valve and check valve, and its structure is shown in figure 1. There are generally two kinds of air hole Settings: one is near the pump exhaust, when the compression chamber and the exhaust is connected, the beginning of aeration; Another is set up on the end cover, when inspiratory, “at the end of the rotor to turn an Angle (10 ° ~ 15 °), air hole, began to aeration. In the aeration process, the pump limit pressure will rise, pumping rate will decline. The noise caused by pump oil impacting the exhaust valve can be reduced by adding a small amount of gas. High-speed straight league pump in the pump with high temperature (90 ℃ ~ 100 ℃), is advantageous to the non-condensable gas extraction.

Pneumatic valve structure

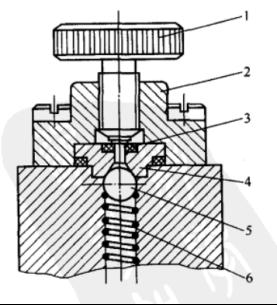

FIG. 1 structure of air ballast valve

1- regulating valve; 2- pneumatic valve seat; 3- gasket; 4 – stop; 5 – steel ball; 6 – spring

In order to prevent oil injection and return to the pump, improve the lubrication condition of the pump and expand the scope of use of the pump, rotary vane pump is also equipped with a variety of accessories, such as oil mist catcher, molecular filter, dust filter, chemical filter, oil filter, etc.. With the improvement of technology and process requirements, the structure of the rotary vane pump is becoming more perfect, the performance is improving.

Related videos

Related Products

Contact us

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.