Online Inquiry

Online Inquiry

When a vacuum system is needed, it must be a vacuum pump equipment. Of course, you want the best solution, which is not only innovative and excellent performance, but also safe and reliable with the lowest cost. This is indeed a challenge. Our professional engineers will spend a lot of time on comprehensive research and analysis of your specific process to determine your needs, and then design the most suitable vacuum / compression system to meet your most basic processing capacity, vacuum or compression pressure and the special performance requirements of your device, so as to provide you with the best cost-effective scheme.

liquid ring compressor advantages :

The inner liquid ring of the liquid ring compressor is usually between 10 ℃ and 50 ℃, because of its cooling effect, the gas compression is basically isothermal.

This feature can avoid the polymerization of gas due to high temperature, for example, it can prevent the polymerization of H2S and ammonia in the refinery tail gas recovery application.

The existence of liquid ring can also prevent any spark in the pump, which is suitable for dealing with all kinds of highly flammable and explosive gases, such as hydrogen and aromatics.

When the inhaled high-temperature water vapor touches the foot cold liquid ring, it will produce condensation, so it actually reduces the volume of the gas to be treated by the pump, which has a high efficiency when dealing with the medium containing a large amount of water vapor or other condensable gas.

There is a large gap between the impeller and the flat disk in the liquid ring compressor, which can deal with the liquid containing a small amount of particles and fibers in the gas, and some gas containing liquid.

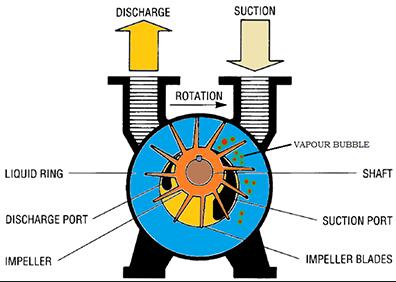

Impeller is the only rotating part of the liquid ring compressor. The rotating impeller has the same function as the piston, vane and screw of the mechanical compressor. Liquid ring compressor is the most suitable choice in many industries, especially in chemical industry.

Chemical gas medium that can be treated

Compared with other vacuum pump, compressor system and liquid ring compressor, it can deal with the following media: water containing input gas, explosive mixed gas, corrosive unclean mixed gas and unpredictable gas due to processing process.

Our goal is to provide customers with reliable, long-life, low maintenance, energy-efficient solutions, such as: evaporation, distillation, vacuum filtration, gas compression, solvent recovery and drying. The typical different application schemes are described as follows:

Explosive gas compression

As a typical scheme to deal with explosive gas, the compression system can make acetylene cool and saturate the sealing liquid water. In this way, the possibility of explosion is minimized.

Polyester reaction

In order to eliminate the blockage caused by excessive polymer particles, glycol is used as the primary fluid in the injector, and glycol liquid can be used as the working fluid of the front liquid ring vacuum pump and the coolant of the intermediate direct cooler. This can extract process impurities from water, steam and air.

We provide a wide range of products and systems for the industry, including: chemical, mine, pharmaceutical, petrochemical, petroleum, biochemical, water treatment, steel, coal chemical.

VCM recycling

In a monomer recovery system, unreacted vinyl chloride is first sent to a storage tank. The liquid ring compressor draws the VCM gas out of PVC, and then delivers the VCM to the compressor inlet with a pressure of one atmosphere or nearly one atmosphere. This single-stage compressor compresses the VCM and condenses it into a pressurized liquid for storage.

Solvent recovery

When the process is intermittent operation, the vacuum rolling dryer needs to increase the vacuum of the casting to pump the solvent at the most appropriate suction speed. If there is a high vacuum at the beginning, the steam in the dryer will be pumped out, which is necessary to transfer the heat to the solid particles. At the end of the drying process, a jet pump using solvent vapor as the primary fluid raises the vacuum to the point where residual solvent can be removed.

PTA filtering

The rotary vacuum filter will produce a lot of water in use, so the liquid ring vacuum pump is the best choice. When there is a failure in the production process, such as failure of the filtrate pump, the droplets will enter the vacuum system. Liquid ring vacuum pump can still work without damage when it is used in this unfavorable situation.

Styrene monomer and polystyrene

The factory needs a lot of vacuum systems, and some vacuum towers require a vacuum of at least 10 mm Hg absolute pressure. In the past, the steam jet jet pump was widely used as the standard vacuum setting, and its main disadvantage was that water vapor would pollute styrene and ethyl benzene. This problem can be solved by using the mixing system of Roots vacuum pump and liquid ring vacuum pump. Vacuum pump can use styrene, ethylene or a mixture of the two as sealing liquid. The hybrid vacuum pump system can not only clear the pollutants, but also save energy.

Sealing fluid

In order to meet the requirements of different media transportation in the chemical industry, our company can use the following media as working fluid to meet the requirements of different working conditions. Water is an excellent sealing fluid and is most commonly used because it is easy to obtain. However, in many cases, some other liquids have advantages that cannot be ignored. Some products even a little water is not allowed. In view of these special conditions, liquid ring vacuum pump / compressor has successfully applied a variety of other liquids as working fluid with its excellent performance: acetic acid, acetic anhydride, acetic acid group, acetone, alcohol, caustic soda, cyanide, hydrocarbon, gasoline, glycol, ethane, kerosene, butanone, oil, sulfuric acid, toluene, xylene, etc.

liquid ring compressor other functions:

Liquid ring vacuum pump, vacuum unit and compressor unit (including corrosion-resistant Series) are widely used in Petrochemical / chemical industry, far more than the above. Another example: vacuum transportation of various materials, compression of flammable and explosive gases such as hydrogen and propylene, vacuum crystallization, drying, PSA, vacuum system on the top of crude oil vacuum distillation, vacuum filtration.

According to your working conditions, we have a variety of materials for you to choose: carbon steel, 304, 304L stainless steel, 316, 316L stainless steel, titanium, Hastelloy, etc.

We provide vacuum pump / compressor system to meet your every process requirement. Our excellent industry engineers will design the most perfect solutions to meet your needs according to the special process and working condition requirements. High quality liquid ring compressor exceeds your expectation in reliable performance, long-term operation, energy saving and easy installation.

Liquid ring compressor

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)